Dehumidifiers

Desiccant Dehumidifier MDC 160

Constructional Features:

- The casing has high resistance to atmospheric corrosion and made of 1,0 mm stainless steel sheet metal; some parts made of 1,5 and 2,0 mmstainless steel in order to achieve rigidity

- Compact design and low weight of the unit

- High performance at low temperatures and low relative humidity in a room

- Optional humidistat is available as an accessory

- Easy access to the internal components of the dehumidifier for the maintenance

- PTC-heater

- EC-fan;

- High efficiency of the washable silica gel rotor

- The design facilitates easy transport by one person

- All components made exclusively by European manufacturers

Technical data:

Process air

Rated airflow – 160 m³/h

Available static pressure 130 Pa

Reactivation air

Rated airflow 45 m³/h

Available static pressure 80 Pa

Power supply

(1х230V, 50 Hz) 1kW

Current 4,6 A

Miscellaneous data

Weight 11 kg

Operating temperature -30/+40˚С

Max noise level

without ductworks 55 dBA

Air filter EU4

IEC protective class IP44

Dimensions:

Changes are possible without notice

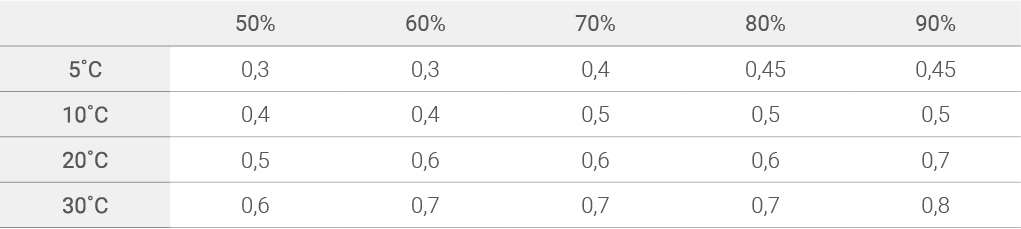

Dehumidification Capacity:

Approximate capacity in kg/h at different inlet process air relative humidity (%) and temperature (˚С)

Key Applications

The dehumidifier is designed to control humidity, maintaining humidity at the required level, drying room.

For the storage of products, materials, raw materials:

- In cold storage / cold storage

- For the storage of grain mass

- In ship repair, shipbuilding industry.

- For the carriage of goods by sea.

- For conservation of power

- For storage of fertilizers

- For the storage and preservation of military technology and equipment

- For the ventilation and air conditioning

- For storage of leather products

- For the storage of fur

- For garages, car parks

- For the basement

- For archives, museums

In manufacturing, production shops, premises and the food industry:

- Industrial dehumidifier for freezing

- Industrial dehumidifier for the production of sausages

- Industrial dehumidifier for sugar production

- Industrial dehumidifier for confectionery production

- Industrial dehumidifier for the production of marshmallows

- Industrial dehumidifier for the production of ice cream

- Industrial dehumidifier for the production of meat products

- Industrial dehumidifier for beer production

- Industrial dehumidifier for the production of dairy products

- Industrial dehumidifier for cheese production

- Industrial dehumidifier for the pharmaceutical industry.

- Industrial dehumidifier for ice arenas, the rink.

- Industrial dehumidifier for the electronics industry, the production of electronics.

High Standards

Our Desiccant dehumidifiers will help you to solve the problems that arise due to increased moisture in the air which are corrosion, product damage, product adhesion, mold and fungi growth on the surfaces. We guarantee that our quality and price ratio is the best in the market.

Vast Experience

Practical experience in the desiccant dehumidification more than 15 years.

Made in Europe

All components made exclusively by European manufacturers.

EU standards

The equipment complies to all of the applicable EU directives and regulations.

Method of Operation

A desiccant dehumidifier removes water from a flow of the air that passes through it. The heart of this process is an adsorption rotor coated with a special substance that absorbs the water molecules that make up the moisture in the passing air (Process air). When saturated, the rotor is rotated over to a regeneration zone, where it is dried with heated air (Reactivation air). The warm, humid regeneration air is led away out of the unit (Wet air) and the rotor is once again ready to absorb water molecules.