Dehumidifiers

Desiccant Dehumidifier MDC 250

The MDC 250 desiccant dehumidifier is designed to efficiently dehumidify air in open system applications. The unit could operate in recirculation mode too. In this case plate with spigots for ductwork connection has to be ordered as additional accessory. The compact construction allows extended periods of operation with a minimum of maintenance. The design facilitates easy transport by one person. Dehumidifier is designed for drying-out buildings, new buildings as well as waterdamaged buildings. Furthermore, it is used for room air dehumidification, dry air storage, water works and pump stations, etc. Especially suitable for low temperature and low humidity operation.

Constructional Features:

- The casing has high resistance to atmospheric corrosion and made of 1,0 mm stainless steel sheet metal; some parts made of 1,5 and 2,0 mmstainless steel in order to achieve rigidity

- Compact design and low weight of the unit

- High performance at low temperatures and low relative humidity in a room

- Optional humidistat is available as an accessory

- Easy access to the internal components of the dehumidifier for the maintenance

- PTC-heater

- High efficiency of the washable silica gel rotor

- The design facilitates easy transport by one person

- All components made exclusively by European manufacturers

Technical data:

Process air

Rated airflow – 290 m³/h

Available static pressure 160 Pа

Reactivation air

Rated airflow 80 m^3/h

Available static pressure 100 Pа

Power supply

(1х230V, 50 Hz) 1,4 kW

Current 6,1 А

Miscellaneous data

Weight 18 kg

Operating temperature -30/+40˚С

Max noise level

without ductworks 61 dBA

Air filter EU4

IEC protective class IP44

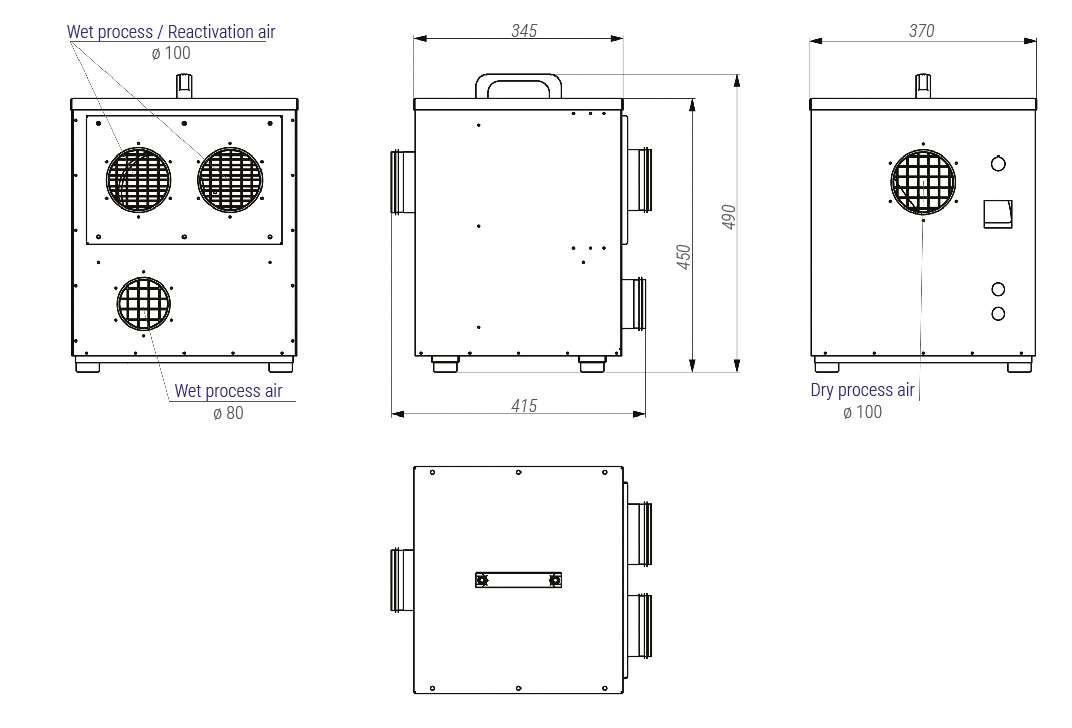

Dimensions:

Changes are possible without notice

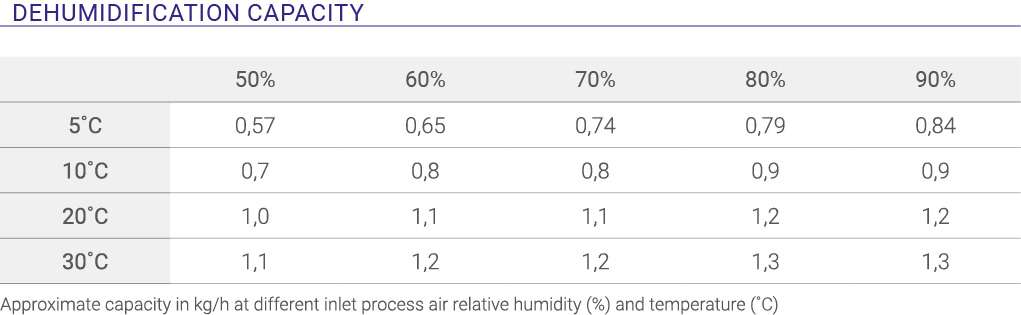

Dehumidification Capacity:

Approximate capacity in kg/h at different inlet process air relative humidity (%) and temperature (˚С)